|

| victorianrailways.net |

PART ONE- SUPER DETAILING & WEATHERING

Well its been a busy few weeks but as posted in my last post I'm doing a three part blog on the new VR T3 that has come out from Aust-N-Rail. For some people super detailing is a process that might end up in the too hard basket, but I'm going to give it ago anyway. This is the first time Ive added detail to a loco. I have seen other people do it and Ive found by talking to them on how they have done it has given me hope that i can too do it. Most of the time its just knowing what people have used that makes the job so much better.

Super Detailing

I will talk about weathering later but first i will go through the steps on what i did to the loco and what i used.

1. Headlights

I first drill out the holes for the headlights and the marker lights. I used a .3mm drill for the maker light holes and a .4mm for the headlights. I used these sizes as i have this already in optic fire. I will talk more about this in part 2. I found drilling the hole a bit tough as the drill bit would get stuck often, i was given a tip after doing this to use a little bit of turps at the end of the drill bit. I wanted to drill out the holes first as before i weathered the loco.

2. Top of the loco

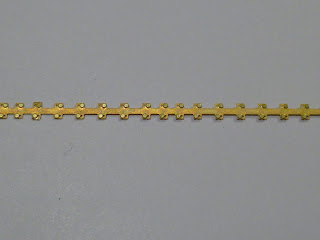

I then went to work on the top of the loco. Using photos of the loco i located and drill .2mm holes for the lift rings (made by BLMA). I also pre-sprayed them and then just super glued them into spot. I than chopped up a Leslie S3L-R horn (BLMA) and than glued it back together to form the right shape for a T class. It was than painted black and glue into position via a .4mm hole. I also noticed in the photos there was a black cap sticking out of the loco near the front lift rings. I have no idea what it is but i used a brass pin head painted black to copy the look. This was also glued in position via a .4mm hole

3. Front Ends

My first plan was to rebuild the front end to set back the top half but i soon found out i that the best way i thought of doing it was going to be to make up a brass etch for it. I don't have time to do it now, maybe one day. So glued in two set of MU horses and brake pipes (BLMA). I also made up an uncoupling bar. This was made from .008" phosphor bronze wire made by Tichy train group. I took me a few goes to get the shape right. It was than painted blue and glued into position

4.The sides

I first played with the fuel tank. I added a pin head for the diesel fuel cap and a piece of .5 x .75mm styrene strip to make a fuel gauge. I then re sprayed the tank in engine black. I also wanted to add some sanding pipes. I had to be carefull with this as it could not foul a turning bogie. I first drill a .2mm hole under each sanding box and than i used and formed the .008" wire to make the pipes. It took a few goes to get it right but I'm happy with the overall look. Than painted them black and glued them into position with the holes i had made. Make sure you dont glue the pipes to the fuel tank. The tank needs be free to take apart the loco.

I did not add windows or wipers to the cab as i need it to be open for the sound to come out!

This is the look im after, well worked locos

Weathering

This is a great topic, some people love it and others hate it. I have a simple rule for this. If the loco is to be running on a layout it should be weathered, if its going to sit behind glass all its life don't weather it.

Once again this is the first time Ive weathered something so i spent some time looking and talking about it. I found the whole process really easy to do.

So for me some of my locos will be strongly weathered and some will be lightly weathered. For this T class it was going to be strong weathered loco to come a cross a well used loco.

I first give the hole loco a wash in a mixture of india ink. I made the wash about 1 part ink to 10 parts water. Maybe a little bit weak but i gave it a couple of coats. I then used a brush, spit and black pastel and rubbed into all the grills, vents and front ends. To get the dusty look i used Floquil "Earth" and than a lighter coat of Polly scale "Mud". Both was air brushed on using a fine mist and with the brush set back a fairway from the loco. Thats all i did for weathering. I'm yet to add a coat of dullcote.

So in the end it was great fun and i found it gave the loco some life. Its not a perfect job but I'm happy with the results. I hope by reading this it may give you some ideas on what to do on your loco and guess what it wasn't that hard to do. Here are some Before and after photos of the loco. First 3 are straight out of the box and the last three are of the finish result for part one.

Remenber to click on the photo to make it bigger

I hope to get part 2 up soon. I'm just chasing a part for the marker lights but I'm hoping to get it this week.

PS. Im looking around for a CNC milling machine if anybody knows of a second hand or new one please email me a

bendigonscale@live.com.au Im looking for a hobby size one.